-

★3-in-1 Tweaking : It allows for the auto adjustment of arm Height, Pitch, and Roll in a single tweaking cycle. This is possible by the two sets of tweaking mechanisms, namely, the Linear Tweaking mechanism when the arm’s height is out; and the Rotary Tweaking mechanism when the arm’s pitch or roll is out.

-

-

★Intelligent Tweaking : The Auto Tweak Machine uses the special software developed by our innovative team that self-learns, self-adjusts, self-adapts and memorizes automatically all previous data and analysis. The machine will not only self-learn from different arm length, thickness, width and elasticity, but also automatically adjust the Tweaking Parameters to adapt to different arm in order to tweak the arm’s center line or arm’s edge to nominal value within 3~4 tweaks.

-

-

★Mean Tweaking : Mean Tweak will tweak the arm to be in the “Mean Tolerance” so that the mean value of the arm height will be able to be controlled in a certain range

-

-

★Speed Tweaking : With the intelligent control, the machine will be able to achieve up to 2 seconds per arm tweaking speed.

-

-

★High Yield Tweaking : It is a special feature preventing undue loss in cycle time. The feature known as One Arm One Tweak or OAOT in short, individually tweaks the arm once for most arms that need tweaking. Further reduction of cycle time can also be achieved through the forward looking control function. This function checks the next tweaking position while conducting the current arm tweaking, thereby negating the need to retract and extend the tweaking blade.

-

-

★Auto-Correlation: Eliminating manual computation errors, the Auto Correlation feature in the Auto Tweak Machine is unique; it allows consistency in accuracy between machines with reference to a Master Part, through a mere click on the menu. The correlation offset data would be automatically set and saved in the database.

Product Specifications

Tweak-able Product

-

✤ Actuator Arm (E-Block)

-

✤ ACA (Actuator Coil Assembly)

-

✤ AFA (Actuator Flex Assembly)

-

✤ APFA (Actuator Pivot Flex Assembly)

Adjustment Type

-

✤ Height

-

✤ Pitch

-

✤ Roll

Tweaking Speed

-

✤ Up to 2 seconds per arm

Tweaking Mode

-

✤ Intelligent Tweak

-

✤ Mean Tweak

-

✤ Normal Tweak

Tolerance Control

-

✤ Edge

-

✤ Thickness

-

✤ Center Line

-

✴ The different fin of the actuator arm can be individually controlled by different types of Tolerance Controls

Tweaking Target Control

-

✤ Upper Edge

-

✤ Lower Edge

-

✤ Center Line

-

✴ The different fin of the actuator arm can be individually controlled by different types of Tweaking Target Controls

Acceptable Measurement Equipment

-

✤ LS-3000 series

-

✤ LS-5000 series

-

✤ LS-7000 series

-

✴ Buyer can use their existing Keyence’s measurement equipments currently used in their manual tweaking process or other processes, to install in their Auto Tweak Machine for effective cost saving.

Other Advantages

-

✤ Auto Correlation

-

✤ OAOT: One Arm One Tweak

-

✤ No Retract Tweak

-

✤ Time Datum Check

-

✤ CPK Statistic

-

✤ Compact Physical Size: 600mm x 510mm x 1480mm (L x W x H).

Once again setting the benchmark for the ultimate in Actuator Arm Adjustment, the new ACD Auto Tweak Machine with built-in intelligent control and statistic management, represents the perfect balance of elegant design, high precision, unmatched tweaking speed, flexible tolerance control, and the latest cutting-edge technologies. Be awed by its unique features and perfect performance in arm height, pitch, and roll adjustment.

Auto Tweak Machine achieves not only Intelligent Tweak but also Mean Tweak in arm height, pitch and roll adjustment. Featuring self-learning, self-adjusting and self-adapting, the machine will self-learn from different arms’ length, thickness, width and elasticity, automatically adjust the tweaking increment step to adapt to different products in order to achieve faster tweaking speed. Some of its key unique, innovative and advantageous features are:

Stainless Steel Cover

Powder-Coated Cover

ACA

AFA

APFA

Actuator Arm

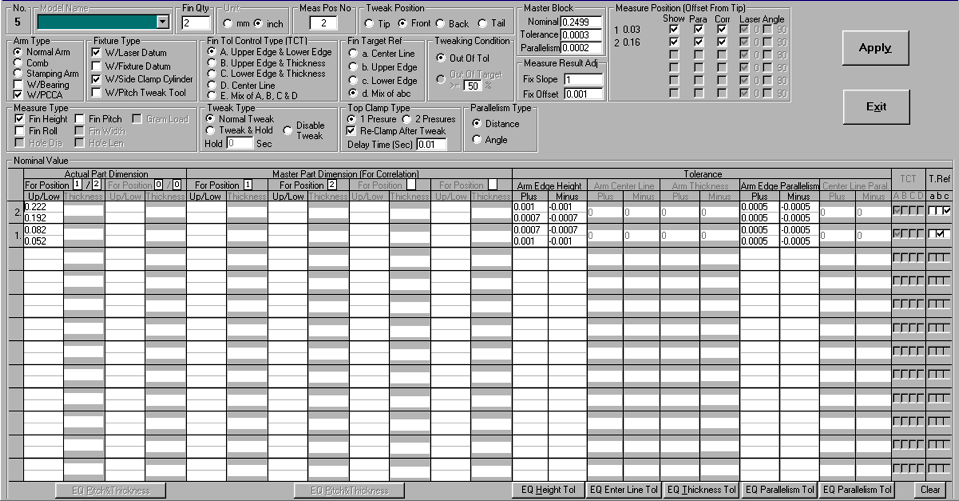

Pre-setting Window:

Operation Window

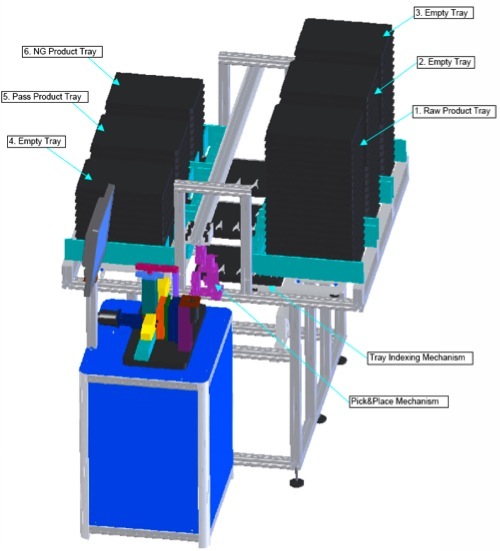

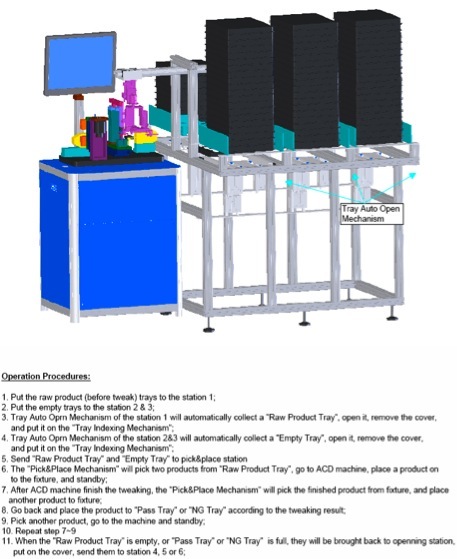

Auto Loading and Unloading System

Auto Tweak Machine (Signature Product)